Understanding Rapid Prototyping Services Suppliers

Rapid prototyping is a crucial component in the product development lifecycle. It enables businesses to transform their innovative ideas into tangible products faster than traditional methods. In this article, we delve into the intricacies of rapid prototyping services suppliers, their significance, and how they can enhance your business operations.

What is Rapid Prototyping?

Rapid prototyping refers to a group of techniques used to quickly create models of a product. These prototypes can be made from various materials and represent different stages of development. The primary goal is to validate designs and functionalities, making it easier to identify possible issues before mass production. The process leverages advanced technologies such as 3D printing, CNC machining, and injection molding.

The Importance of Rapid Prototyping

In today’s competitive landscape, the ability to innovate quickly is paramount. Companies that incorporate rapid prototyping into their workflow can:

- Reduce Time to Market: Quickly turning concepts into prototypes speeds up the entire development process.

- Enhance Design Accuracy: Physical models allow for precise adjustments and testing.

- Facilitate Better Communication: Prototypes provide a tangible reference for team discussions and client presentations.

- Cut Costs: Identifying flaws early reduces unnecessary expenses associated with rework.

How to Choose the Right Rapid Prototyping Services Supplier

Selecting the right rapid prototyping services suppliers is crucial for success. Here are essential factors to consider:

1. Experience and Expertise

Look for suppliers with a proven track record in your industry. Their experience will influence the quality of the prototypes and responsiveness to your needs.

2. Technologies Offered

Different projects require different technologies. Ensure the supplier offers the latest methods in rapid prototyping such as:

- 3D Printing

- CNC Machining

- Injection Molding

- Laser Cutting

3. Material Selection

Materials play a significant role in prototype functionality and appearance. Quality suppliers should offer a range of materials such as:

- Plastics (ABS, PLA, Nylon)

- Metals (Aluminum, Stainless Steel)

- Wood and Composites

4. Lead Times and Flexibility

Fast lead times are a hallmark of effective rapid prototyping services suppliers. Be sure to discuss the typical turnaround and ask about their ability to accommodate urgent requests.

5. Quality Assurance Processes

Reliable suppliers implement rigorous quality checks. Understanding their QA processes can provide peace of mind regarding the final product quality.

Benefits of Partnering with Rapid Prototyping Services Suppliers

Cost-Effective Development

By detecting design flaws early, companies can save significant costs associated with late-stage modifications. Rapid prototyping services suppliers help avoid costly mistakes and enable better budgeting for future production.

Increased Innovation

The ability to create multiple prototypes allows teams to experiment with different designs quickly. This fosters innovation and creativity within the team.

Improved User Testing

Prototypes can be tested with end users to gather valuable feedback. This insight is crucial for refining the product before it hits the market.

Applications of Rapid Prototyping Across Industries

Rapid prototyping is beneficial across multiple sectors:

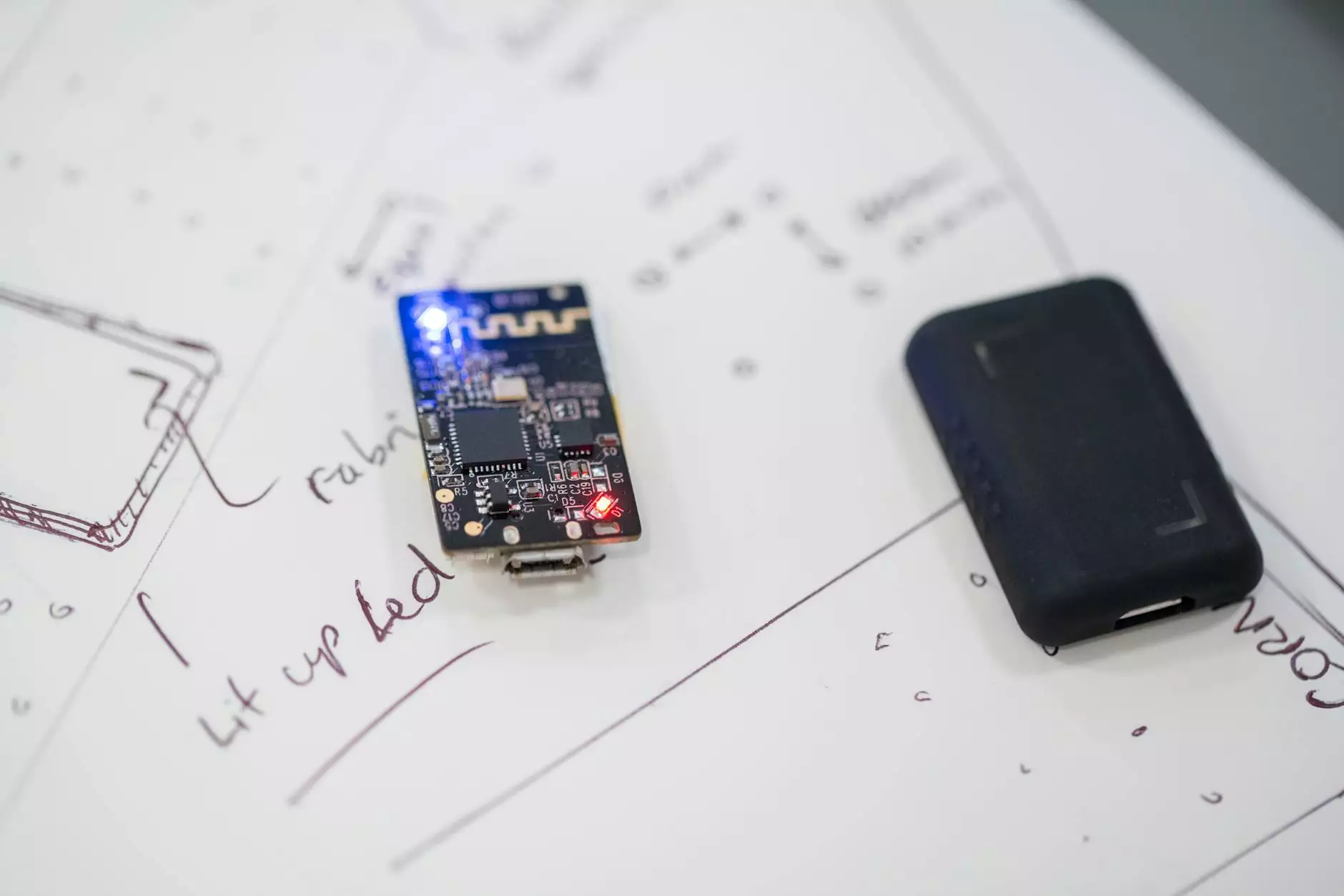

1. Consumer Electronics

Rapid prototyping helps in developing sleek and user-friendly designs. Companies can quickly iterate based on consumer feedback.

2. Automotive Industry

In the automotive sector, rapid prototyping enables the testing of components before mass production, ensuring quality and safety.

3. Medical Devices

For medical devices, prototypes can be created to ensure compliance with regulatory standards and usability for medical professionals.

4. Aerospace

The aerospace industry benefits from prototyping to test new concepts that require both high durability and low weight, a delicate balance that can be achieved through advanced prototyping techniques.

Success Stories: Companies That Thrived with Rapid Prototyping

Numerous companies have successfully leveraged rapid prototyping services suppliers to boost their product development:

Case Study: Tech Innovator

Once struggling with lengthy product cycles, Tech Innovator partnered with a rapid prototyping supplier, reducing their development time by 60%. Their ability to test and iterate prototypes rapidly allowed them to release a groundbreaking device within a year.

Case Study: Automotive Pioneer

A leading automotive pioneer used rapid prototyping to develop a new safety feature in record time, ensuring they stayed ahead of regulatory requirements while greatly improving their vehicle’s safety ratings.

Conclusion

Investing in rapid prototyping services suppliers can significantly elevate your business’s ability to innovate and compete. By understanding the benefits and selecting the right partners, companies can achieve accelerated product development while ensuring quality and adaptability. Whether you’re in consumer electronics, automotive, medical, or aerospace, rapid prototyping is your gateway to success in product innovation.

Get Started with DeepMould

If you’re ready to take your product development to the next level, visit DeepMould today. Our team of experts is equipped to deliver exceptional rapid prototyping services tailored to your unique business needs. Let’s turn your ideas into reality!