Piston Motor Spare Parts Manufacturer: Ensuring Quality and Performance

In the realm of automotive engineering, piston motor spare parts play a vital role, especially in diesel engines. As a leading piston motor spare parts manufacturer, Client-Diesel is committed to delivering products that meet the highest standards of quality and durability. This article delves deep into the significance of piston parts in diesel engines, the intricate manufacturing processes involved, and how choosing the right spare parts suppliers can significantly impact your business operations.

Understanding Diesel Engines and Their Components

Diesel engines are renowned for their efficiency, durability, and power. They operate on the principle of compression ignition, which allows for higher fuel efficiency compared to traditional gasoline engines. A core component of this system is the piston, which transforms the linear motion into rotational power, ultimately driving the mechanical systems of the vehicle.

The Role of Pistons in Diesel Engines

The piston is a critical component that must withstand extreme conditions, including high temperatures and pressures. With that in mind, here are some reasons why the quality of pistons and their spare parts is essential:

- Performance and Efficiency: Quality pistons ensure optimal performance, improving fuel efficiency and reducing emissions.

- Durability: Well-manufactured pistons have enhanced lifespan, decreasing the need for frequent replacements.

- Engine Health: High-quality pistons help maintain overall engine health by minimizing wear and tear, thus ensuring longevity.

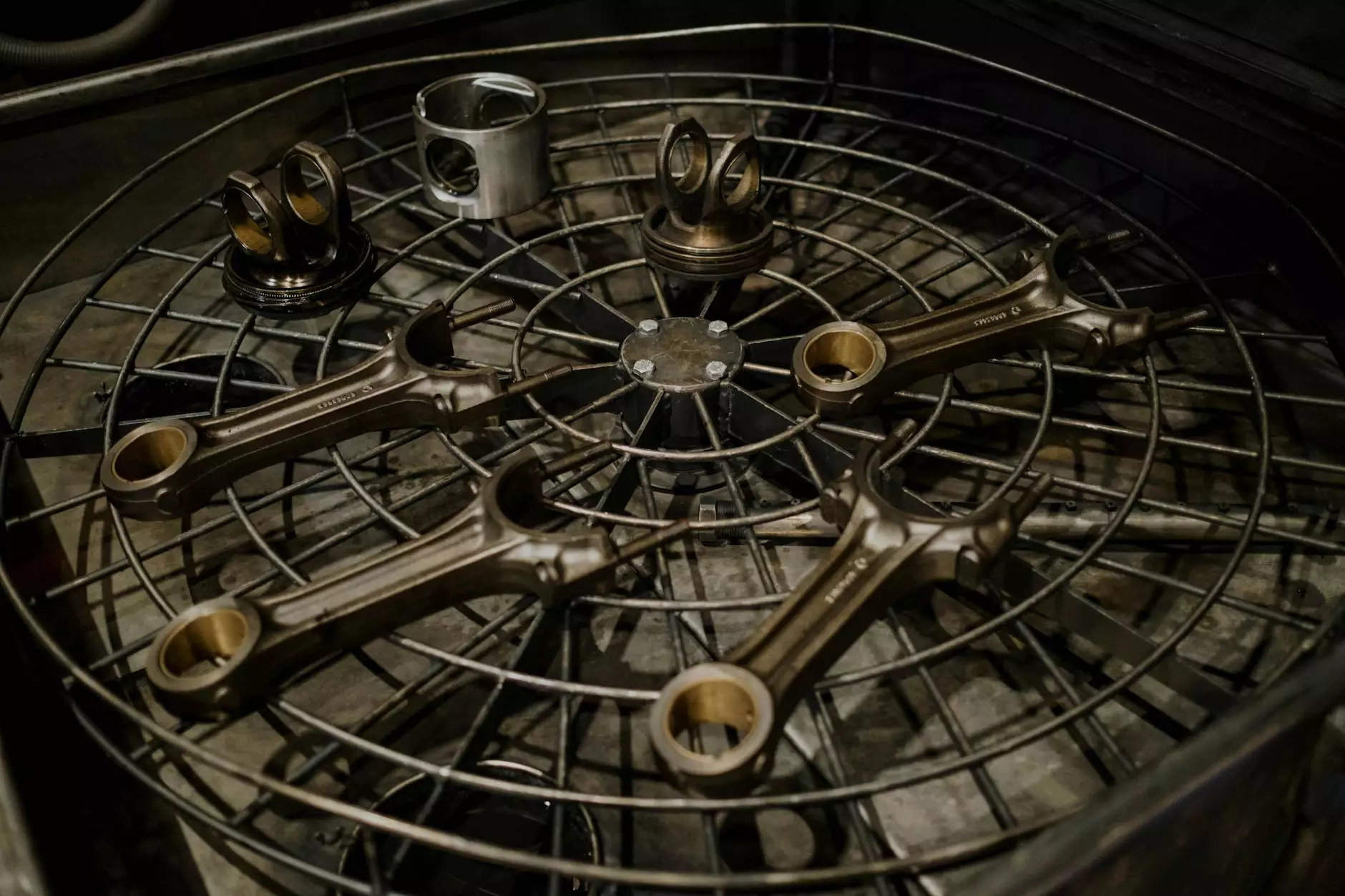

Piston Motor Spare Parts: Types and Functions

Understanding the various piston motor spare parts is crucial for any business involved with diesel engines. Here’s a detailed breakdown of the main types of spare parts:

1. Piston Rings

Piston rings create a seal between the piston and the cylinder wall, preventing the escape of gases and ensuring that lubrication remains effective. They are essential for:

- Maintaining compression within the cylinder.

- Preventing oil from entering the combustion chamber.

- Enhancing the overall efficiency of the engine.

2. Piston Pins

Piston pins connect the piston to the connecting rod. They facilitate smooth motion and conversion of the crankshaft’s rotational movement to the reciprocating motion of the piston. Key functions include:

- Allowing the piston to pivot freely.

- Enabling optimal engine performance.

3. Piston Skirts

The undersides of pistons, known as skirts, help to stabilize the motion while ensuring proper alignment within the cylinder. This contributes to:

- Reducing friction and wear.

- Maintaining structural integrity under various operational conditions.

Piston Motor Spare Parts Manufacturing Process

The manufacturing of piston motor spare parts is a complex process that requires precision and expertise. At Client-Diesel, our production process includes several fundamental steps to ensure quality:

1. Material Selection

Choosing the right materials—such as high-grade aluminum alloys or cast iron—is crucial. These materials must be lightweight yet durable to withstand the harsh conditions of diesel engines.

2. Machining

Advanced CNC (Computer Numerical Control) machining processes guarantee that every part meets exact specifications. This step includes:

- Turning, milling, and drilling operations to achieve precise geometries.

- Inspection of dimensions and surface finish to ensure optimal quality.

3. Heat Treatment

Heat treatment processes enhance the strength and resistance of the parts to wear and fatigue. This step is vital for maintaining performance over time.

4. Finishing

Final touches include surface coatings and polishing to reduce friction, increase wear resistance, and enhance aesthetics.

Choosing the Right Piston Motor Spare Parts Supplier

Selecting a reliable spare parts supplier is essential for ensuring your diesel engine operations run smoothly. Here are some tips for choosing the right supplier:

1. Quality Assurance

A reputable supplier should demonstrate adherence to quality standards, such as ISO certification. They should also provide quality assurance documentation for their parts.

2. Product Range

Your ideal supplier should offer a comprehensive range of products, including various piston types, piston rings, and other essential components tailored for different engine models.

3. Customer Support

Effective customer service is critical. Assess their responsiveness to inquiries, willingness to provide technical support, and after-sales service.

4. Competitive Pricing

Price can be a deciding factor, but ensure that you balance cost against quality. Cheaper parts may lead to higher costs over time due to early failures.

The Importance of Regular Maintenance and Quality Parts

Regular maintenance of diesel engines is paramount for extending their lifespan and enhancing their efficiency. Utilizing high-quality piston motor spare parts plays a significant role in this process. Here are some maintenance tips:

- Conduct regular inspections of piston components to catch early signs of wear.

- Follow the manufacturer's recommended maintenance schedules for oil changes and parts replacements.

- Use synthetic or high-quality oils to minimize friction and wear on piston rings and skirts.

Conclusion

In conclusion, as a prominent piston motor spare parts manufacturer, Client-Diesel is dedicated to providing top-notch diesel engine components that guarantee performance, reliability, and durability. Choosing the right spare parts and suppliers is essential for the success of any diesel engine operation. By investing in quality parts and adhering to a stringent maintenance regimen, businesses can ensure success in their endeavors while optimizing operational costs.

For further information about our products and services, or to explore our extensive range of diesel engine spare parts, please visit our website at Client-Diesel.