GW Plastics Vermont: Innovating in Electronics and Medical Supplies

GW Plastics, based in Vermont, stands as a testament to innovation, quality, and excellence in the manufacturing sector. As a leading provider of precision-engineered solutions, GW Plastics not only meets but exceeds the expectations of the electronics and medical supplies industries. This article delves into the remarkable capabilities of GW Plastics and how they are redefining the landscape of manufacturing through superior technology and practices.

1. Overview of GW Plastics

Founded with a vision to revolutionize manufacturing processes, GW Plastics has grown from a modest operation to a powerhouse in Vermont's industrial sector. The company specializes in:

- Electronics Manufacturing

- Medical Device Production

- Custom Molding Solutions

- Precision Engineering

With over four decades of experience, GW Plastics has cultivated a reputation for reliability and precision. Their commitment to innovation, along with a skilled workforce, allows them to tackle complex challenges and provide tailored solutions to various industries.

2. Expertise in Electronics

The electronics industry requires a unique set of manufacturing skills and technologies, and GW Plastics has positioned itself as a leader in this realm. Their approach to electronics manufacturing includes the following:

2.1 Advanced Manufacturing Techniques

Utilizing state-of-the-art machinery, GW Plastics employs advanced manufacturing techniques such as:

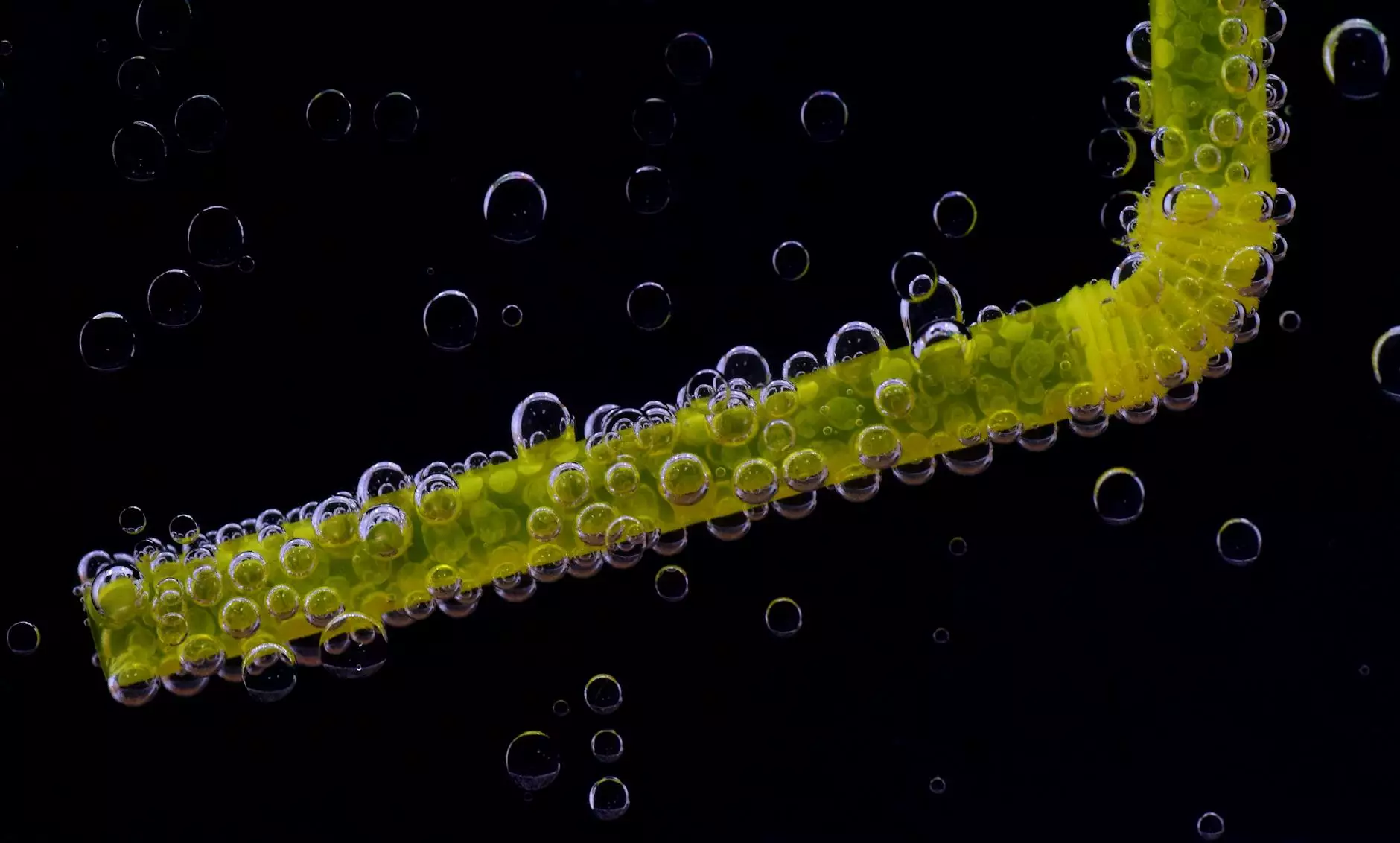

- Injection Molding: Essential for creating precision parts with tight tolerances.

- 3D Printing: Enabling rapid prototyping and shortened lead times.

- Assembly Services: Providing a complete solution from concept to finished product.

2.2 Quality Assurance Practices

Quality assurance is paramount in electronics manufacturing. GW Plastics implements rigorous testing and quality control processes to ensure that every product meets strict industry standards. Their dedication to quality not only reduces defects but also fosters customer trust and satisfaction.

3. Pioneering Medical Device Manufacturing

In the realm of medical supplies, GW Plastics has made significant strides, providing critical components and devices that improve patient care and safety. The company’s emphasis on quality and regulatory compliance makes it a preferred partner in the medical industry.

3.1 Understanding Regulatory Standards

Medical devices are subject to strict regulations. GW Plastics adheres to guidelines from:

- FDA (Food and Drug Administration)

- ISO (International Organization for Standardization)

- IEC (International Electrotechnical Commission)

This compliance ensures that products not only meet current standards but are also safe and effective for patient use.

3.2 Innovative Medical Solutions

The company produces a variety of medical products, including:

- Surgical Instruments

- Diagnostic Equipment

- Wearable Health Devices

Each product is designed with the utmost care, ensuring they are both functional and reliable under pressing medical conditions.

4. Sustainability Initiatives at GW Plastics

As the world moves towards sustainability, GW Plastics is committed to reducing its environmental footprint. The company implements several sustainable practices, including:

- Waste Reduction Programs: Initiatives aimed at minimizing scrap material and promoting recycling.

- Energy Efficiency: Upgrading machinery to lower energy consumption.

- Biodegradable Materials: Researching and using eco-friendly materials in production.

These efforts not only help the environment but also resonate with customers, making them more likely to support brands that prioritize sustainability.

5. The GW Plastics Advantage

What sets GW Plastics apart in the marketplace? The key differentiators include:

5.1 Customized Solutions

Every industry has unique needs, and GW Plastics excels at providing customized solutions tailored to individual client requirements. Their engineering team works closely with customers to develop products that meet specific performance criteria.

5.2 Skilled Workforce

The employees at GW Plastics are highly skilled and trained in the latest manufacturing technologies and practices. Continuous training ensures that the workforce remains at the forefront of innovation.

5.3 Customer-Centric Approach

GW Plastics prioritizes customer satisfaction by maintaining open lines of communication, timely deliveries, and comprehensive support throughout the manufacturing process. This customer-centric approach fosters long-lasting client relationships.

6. Case Studies of Success

GW Plastics has numerous success stories that exemplify their expertise and dedication. Here are a few notable case studies:

6.1 Electronic Component Success

In a recent project for a leading electronics manufacturer, GW Plastics provided complex molded components that required precise tolerances and high durability. Through their advanced injection molding capabilities, they successfully delivered the components on time, exceeding quality expectations and maintaining the client’s trust.

6.2 Medical Device Innovation

In another instance, GW Plastics was approached to develop a new medical device for patient monitoring. By leveraging their engineering expertise and compliance knowledge, they collaborated closely with the client to create a product that not only met regulatory standards but also enhanced patient outcomes.

7. Future Directions for GW Plastics

The future is bright for GW Plastics as they continue to innovate and expand their offerings in both the electronics and medical supplies sectors. With a focus on:

- Research and Development: Investing in new technologies and materials.

- Global Expansion: Reaching new markets and exploring international partnerships.

- Enhanced Sustainability: Continuously improving eco-friendly practices.

GW Plastics is poised to remain a leader in manufacturing, setting new benchmarks for quality and innovation.

8. Conclusion

In summary, GW Plastics Vermont exemplifies excellence in manufacturing with its robust capabilities in the electronics and medical supplies sectors. Their commitment to quality, customer satisfaction, and sustainable practices positions them as a frontrunner in the industry. By choosing GW Plastics, clients are assured of receiving top-notch solutions that are both reliable and innovative, paving the way for future success.